Brushless or Brushed; Which Motor Is Better For My Mill or Lathe?

For those new to the world of motors for metal working machines. Some will wonder what brushless motors are and how they compare to brushed motors. Below is information from Wikipedia on the subject. However, if you’re looking to just know which one is best…I’ll just give you my experience on the subject right up front.

Brushed Motors – I’ve had many good brushed motors over the years (what brushed motors are is explained further below). On the plus side; they’re cheap to buy. The down side is that often they’re much larger than brushless motors for the same power, they have wearable brushes, the typically are much less efficient with their use of electricity which means they can run hot, usually have an open body for cooling…which means you might get metal chips in there and they won’t adjust to load changes like a brushless will. That being said, if you’re on a very thin budget, this might be a good choice.

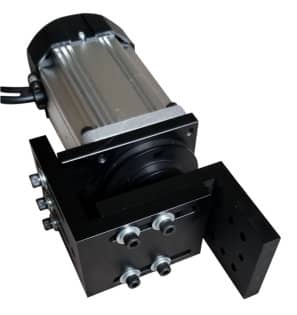

Brushless Motors – Over the years we’ve swapped to only using brushless motors on our equipment. In fact, I would say these have become the most desirable type of motor to power spindles for benchtop lathe and mill owners. They can produce a ton of power from a very compact size motor frame, they’re excellent at automatically adjusting for work load to maintain RPM, commercial drivers allow for easy CNC hookup, they last a very long time without any maintenance, quiet, smooth and very efficiently use electricity, and runs cooler than brushed motors. In a nutshell, if you have the budget, then this is the way to go.

Keep in mind that not all brushless motors and controllers are of the same quality. The old saying is true; “You get what you pay for”. I’ve bought cheap brushless motors with very mixed results. Some ran well, but many had issues including drivers that literally burned up. For that reason, you’ll want to consider getting a better-quality motor set. Of course, that’s all must my take on things and you’ll need to make your own decision. Hopefully, this gave you a little bit of insight.

– James, GlockCNC.com

More Information:

Brushless DC electric motor (BLDC motors, BL motors) also known as electronically commutated motors (ECMs, EC motors), or synchronous DC motors, are synchronous motors powered by DC electricity via an inverter or switching power supply which produces an AC electric current to drive each phase of the motor via a closed loop controller. The controller provides pulses of current to the motor windings that control the speed and torque of the motor.

The construction of a brushless motor system is typically similar to a permanent magnet synchronous motor (PMSM), but can also be a switched reluctance motor, or an induction (asynchronous) motor.[1]

The advantages of a brushless motor over brushed motors are high power to weight ratio, high speed, and electronic control. Brushless motors find applications in such places as computer peripherals (disk drives, printers), hand-held power tools, and vehicles ranging from model aircraft to automobiles.

Brushless vs. brushed motors

Brushed DC motors were invented in the 19th century and are common. Brushless DC motors were made possible by the development of solid state electronics in the 1960s.[2]

An electric motor develops torque by alternating the polarity of rotating electromagnets attached to the rotor, the rotating part of the machine, and stationary magnets on the stator which surrounds the rotor.[3] One or both sets of magnets are electromagnets, made of a coil of wire wound around an iron core. DC running through the wire winding creates the magnetic field, providing the power which runs the motor. However, each time the rotor rotates by 180° (a half-turn), the position of the north and south poles on the rotor are reversed. If the magnetic field of the poles remained the same, this would cause a reversal of the torque on the rotor each half-turn, and so the average torque would be zero and the rotor would not turn.[4][5] Therefore, in a DC motor, in order to create torque in one direction, the direction of electric current through the windings must be reversed with every 180° turn of the rotor (or turned off during the time that it is in the wrong direction). This reverses the direction of the magnetic field as the rotor turns, so the torque on the rotor is always in the same direction.

Commutator

In brushed motors, invented in the 19th century, this is done with a rotary switch on the motor’s shaft called a commutator.[3][5][4] It consists of a rotating cylinder divided into multiple metal contact segments on the rotor. The segments are connected to wire electromagnet windings on the rotor. Two or more stationary contacts called “brushes”, made of a soft conductor like graphite press against the commutator, making sliding electrical contact with successive segments as the rotor turns, providing electric current to the windings. Each time the rotor rotates by 180° the commutator reverses the direction of the electric current applied to a given winding, so the magnetic field creates a torque in one direction.

Disadvantages of commutator

The commutator has many engineering disadvantages that has led to the decline in use of brushed motors. These disadvantages are:[3][5][4]

The friction of the brushes sliding along the rotating commutator segments causes power losses that can be significant in a low power motor.

The soft brush material wears down due to friction, creating dust, and eventually the brushes must be replaced. This makes commutated motors unsuitable for low particulate or sealed applications like hard disk motors.

The resistance of the sliding brush contact causes a voltage drop in the motor circuit called brush drop which consumes energy.

The repeated abrupt switching of the current through the inductance of the windings causes sparks at the commutator contacts. These are a fire hazard in explosive atmospheres, and create electronic noise, which can cause electromagnetic interference in nearby microelectronic circuits.During the last hundred years high power DC brushed motors, once the mainstay of industry, were replaced by alternating current (AC) synchronous motors. Today brushed motors are only used in low power applications or where only DC is available, but the above drawbacks limit their use even in these applications. Brushless motors were invented to solve these problems.[citation needed] Brushless solution

The development of semiconductor electronics in the 1970s allowed the commutator and brushes to be eliminated in DC motors. In brushless DC motors, an electronic servo system replaces the mechanical commutator contacts.[3][5][4] An electronic sensor detects the angle of the rotor, and controls semiconductor switches such as transistors which switch current through the windings, either reversing the direction of the current, or in some motors turning it off, at the correct time each 180° shaft rotation so the electromagnets create a torque in one direction. The elimination of the sliding contact allows brushless motors to have less friction and longer life; their working life is only limited by the lifetime of their bearings.

Brushed DC motors develop a maximum torque when stationary, linearly decreasing as velocity increases.[6] Some limitations of brushed motors can be overcome by brushless motors; they include higher efficiency and a lower susceptibility to mechanical wear. These benefits come at the cost of potentially less rugged, more complex, and more expensive control electronics.

A typical brushless motor has permanent magnets which rotate around a fixed armature, eliminating problems associated with connecting current to the moving armature. An electronic controller replaces the brush/commutator assembly of the brushed DC motor, which continually switches the phase to the windings to keep the motor turning. The controller performs similar timed power distribution by using a solid-state circuit rather than the brush/commutator system.

Brushless motors offer several advantages over brushed DC motors, including high torque to weight ratio, more torque per watt (increased efficiency), increased reliability, reduced noise, longer lifetime (no brush and commutator erosion), elimination of ionizing sparks from the commutator, and overall reduction of electromagnetic interference (EMI). With no windings on the rotor, they are not subjected to centrifugal forces, and because the windings are supported by the housing, they can be cooled by conduction, requiring no airflow inside the motor for cooling. This in turn means that the motor’s internals can be entirely enclosed and protected from dirt or other foreign matter.

Brushless motor commutation can be implemented in software using a microcontroller or microprocessor computer, or may alternatively be implemented in analogue hardware, or in digital firmware using an FPGA. Commutation with electronics instead of brushes allows for greater flexibility and capabilities not available with brushed DC motors, including speed limiting, “micro stepped” operation for slow and/or fine motion control, and a holding torque when stationary. Controller software can be customized to the specific motor being used in the application, resulting in greater commutation efficiency.

The maximum power that can be applied to a brushless motor is limited almost exclusively by heat;[citation needed] too much heat weakens the magnets and will damage the winding’s insulation.

When converting electricity into mechanical power, brushless motors are more efficient than brushed motors. This improvement is largely due to the frequency at which the electricity is switched determined by the position sensor feedback. Additional gains are due to the absence of brushes, which reduces mechanical energy loss due to friction. The enhanced efficiency is greatest in the no-load and low-load region of the motor’s performance curve.[citation needed] Under high mechanical loads, brushless motors and high-quality brushed motors are comparable in efficiency.[citation needed][disputed – discuss]

Environments and requirements in which manufacturers use brushless-type DC motors include maintenance-free operation, high speeds, and operation where sparking is hazardous (i.e. explosive environments) or could affect electronically sensitive equipment.

The construction of a brushless motor may resemble that of a stepper motor. Unlike a stepper, a brushless motor is usually intended to produce continuous rotation. Stepper motors generally do not include a shaft position sensor for internal feedback of the rotor position. Instead a stepper controller will rely on a sensor to detect the position of the driven device. They are frequently stopped with the rotor in a defined angular position while still producing torque. A well designed brushless motor system can also be held at zero rpm and finite torque.