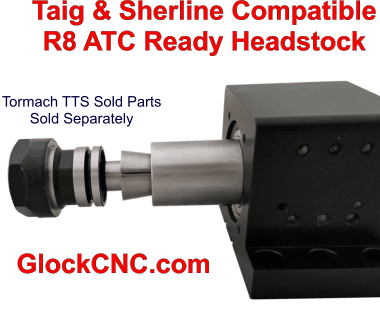

Sherline R8 Headstock – Automatic Tool Changer Ready

NOTE: This product design has been updated. Please go here: https://glockcnc.com/r8-mill-headstock/

The Sherline headstock is good for small basic hobby milling. However, when more options are required, then the R8 headstock becomes a much better choice. Some benefits are:

- Larger cutters can be held compared to the tiny OEM MT1 or ER16 spindle

- Wider variety of cutter options

- R8 End Mill holders and R8 ER tool holders are sold by a ton of vendors

- The Tormach Tooling System (TTS) can be used for ATC or rapid tool changing

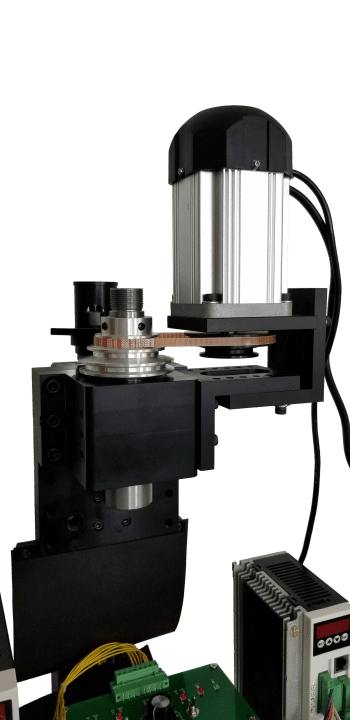

I’m sure you can think of other benefits yourself. Because we also wanted a more robust mill, we engineered a new R8 headstock for Sherline mills. However, some changes needed to be made.

The OEM headstock casing wouldn’t realistically fit the bearing size required for the R8 spindle arbor. The bearings would need to be far to “thin” to work within the OEM headstock. So, we build a Heavy Duty headstock casing that would accept 62mm OD bearings. The headstock is a direct fit to the Sherline mill and motor (however, we do recommend a more powerful motor. We offer a couple of options for that). Plus, a larger headstock offers better vibrational dampening when cutting. This can result in better precision and finish on cuts.

Bearings

Let’s talk bearings. Bearings are a major part of the headstock assembly and often represent the biggest part of the investment. As a standard, we provide ABEC-5 deep groove bearings (if I recall correctly, Sherline OEM bearings are a low grade ABEC-1…the higher the ABEC number, the better). Many of our customers require very high precision. Because of that, we offer ABEC-7 deep groove, ABEC-7 angular contact and ABEC-9 angular contact bearing options for your Sherline R8 headstock. If you order ABEC-9, which is the gold standard in precision, we also do a secondary grind operation. In other words, after the headstock assembly is complete, we grind the collet mating surface. This allows the spindle run-out to match the bearings precision. As a result, you now have a 50 millionth runout spindle!

Upgrades?

The beautiful part about your new headstock is this; if you decide to upgrade to a custom machine or even swap to a Taig mill, you can still use your new headstock. Your headstock will have flanged sides for additional mounting options. Or if you decide to switch to a Taig mill, you can get our adapter plate (which also doubles as an ATA quick change lathe tool holder mount).

Quick Tool Changer & ATC

For those interested in ATC (Automatic Tool Changer), you found the right headstock. You can use the Tormach Tooling System (TTS) for just that reason. Using the TTS, you can even change out your cutter super-fast manually. If you’re interested in going with ATC, then adding a pneumatic cylinder, Belleville washers and longer pull-bar will do the trick (Because other vendors can sell the pneumatic parts and Belleville washers cheaply, we don’t sell them ourselves. Designing the ATC system will be up to you.).

Quick Note: You’ll notice that we don’t have a “tommy bar” to hold the R8 spindle while using a wrench to loosen the tool holder. This is because it’s slow and doesn’t even make sense to do anymore to use a wrench. We simply use a cordless electric impact driver, a socket adapter and socket to loosen and tighten the R8 tool holders. In most cases, it’s actually much faster to manually change tooling this way than to use a small ATC system.