Sherline Spindle-Headstock Upgrades

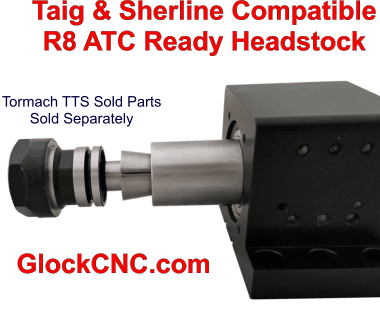

It boils down to what your needs are. For many, they need a wide variety of cutter capacities. This means R8 is the favored spindle type. You can get all kinds of cutters in the R8 size and use metric or English collets. Many like the idea of a nice facing mill or shell cutter for this. There are two challenges to the standard Sherline headstock casing for this; 1) The isn’t much “meat” or mass in the headstock and 2) because of that, you can’t even bore out the headstock very much for a larger bearing. We know because we tried. Don’t get me wrong, we can put a R8 spindle in the OEM casing, but it doesn’t make much sense. So, we engineered our own Heavy Duty Headstocks.

This allowed us to use our full line of spindles (you can find specific information in the website menu above):

- BT-30 Super Popular and Most Robust Headstock

- ISO-20

- R8 – Often used with Tormach Tooling System

- ER25

- ER32

- ER40

- the massive ER50

Fruit Flies, Watches, Titanium & Bearings

Anybody that’s been around machines for awhile knows that bearings are a major key when it comes to accuracy, speed and vibration and heat energy transfer. We saw immediately that the small Sherline OEM bearings could use an upgrade. They are fine for their intended purpose, but our needs demanded different bearings. You can now get 62mm OD bearings in our heavy duty headstocks. This helps with vibration-heat energy transfer. Next, we wanted to really dial down the runout.

The standard GlockCNC bearing is ABEC-5 deep groove. However, some have very specific needs when it comes to accuracy. In fact, one of our customers bought from us a headstock to use as a surgical instrument. He’s brain scientist from UCLA and needed to “window” a fruit flies head to access the brain using a .0005″ diameter cutter (you read it right, a five ten-thousandths of an inch diameter cutter). For this, he needed very high end bearings (he also used our Absolute Zero adjustable ER nut to dial down any remaining runout). Since the project, we’ve added ABEC9 bearings and mounted spindle secondary grind operations to the collet mating surface. This gives you the absolute best runout numbers possible in to the millionths.

Other clients really need more mass and more bearing surface area for cutting hard to cut metals. An example of that is titanium. You might not be working with Ti, but this will give you an idea of why others like the GlockCNC Heavy Duty headstocks so much. Some watchmakers and knife makers seem to gravitate towards this metal. Which I get, it’s a cool metal, light and strong. To get the best results possible from their mill, very good energy management is a must. Ever after bracing up the Sherline for the job, many discovered that the headstock became the weak link. Because of this, we sell our headstocks all over the world for people and companies with specialized needs. When you combine more headstock mass, larger bearing contact surface area and a spindle with more mass…one can achieve far better results. The spindles we use typically have a 30mm OD and the bearings, as previously mentioned, have a 62mm OD (30mm ID, we shrink fit the bearings onto the spindle arbor).

Features:

- Your choice of Sherline OEM headstock casing or our Heavy Duty Commercial Headstock casing.

- Sealed Deep Groove or Angular Contact Bearing options

- ABEC-5 & ABEC-7 OEM Sherline headstocks

- Also, ABEC-9 Angular Contact option for GlockCNC Heavy Duty Headstocks

- Mounts directly to Sherline mills & lathes

- Taig Lathe or Mill will require our adapter

- Heavy Duty Headstocks have much larger 62mm OD bearings for superior life and workload

- ER through hole of .53″ and .79″ option for ER32, 40, 50